Fuse was appointed by the University of York to convert the Grade II listed Derwent P Building into new student accommodation. The scheme comprises of 57 new one bed ensuite rooms, with shared communal kitchens, the accommodation is provided within 6 cluster groups, across 3 floors.

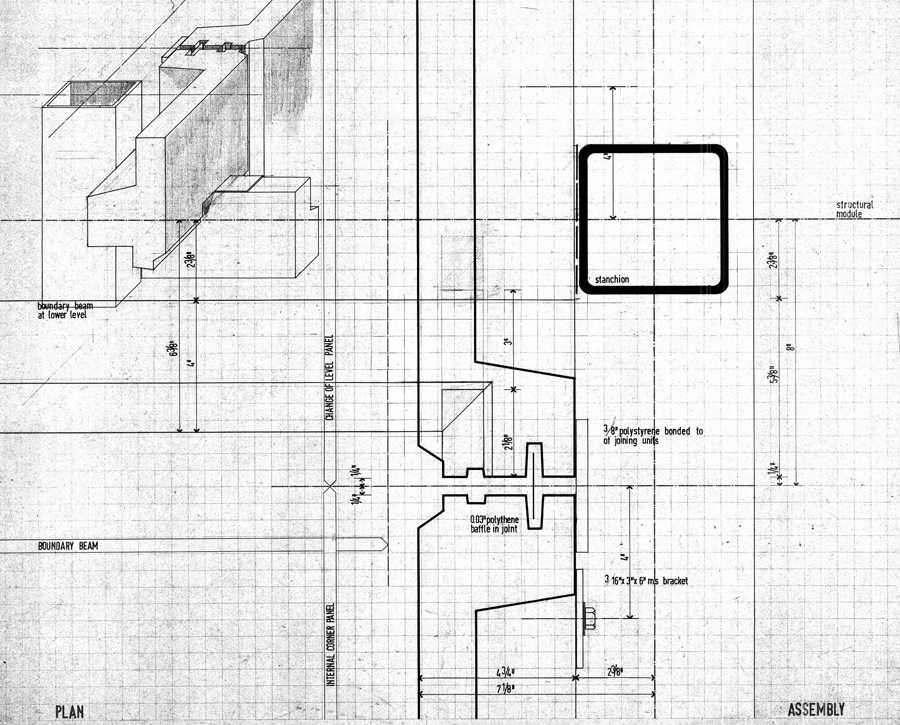

The Former Langwith (Derwent) College was built from 1963 to 1967, the majority of which was completed by 1965; with Block P added as an extension in 1967. The college was built using Mark 3B of the CLASP (Consortium of Local Authorities Special Programme) system. This was a prefabricated, modular system using cold-rolled steel frames clad in pre-cast concrete panels.

Designed by architect Alan Crawshaw (the architect also responsible for Derwent), Block P was built across three floors on a similar layout across each floor. The steel frame supported a felt-covered flat roof, and in communal areas, pyramidal skylights were used to provide light and add interest. Bedrooms facing onto the lakes also had some projecting ‘oriel’ windows to increase light, although more of these are found in Derwent. The concrete wall panels were finished in a grey Trent River Gravel exposed aggregate. The original windows were in softwood, with aluminium opening lights and coloured vitreous enamel panels below.

Client: University of York / Sector: Student Accommodation / Status: Complete / Photography: Fuse Studios & Lindum Group

Due to the nature of the building fabric, the building’s listed status, the location of the project in the wider University campus surroundings, and the stringent wildlife stipulations set out by the local authority environmental department, the project had to be meticulously planned from the Pre-Construction phase, right through to handover. This ensured the overall scheme was delivered with minimal fuss, ensuring several critical Planning and Heritage Conditions were addressed and factored into the programme.

Our approach to upgrading the existing façades thermal and acoustic performance, was guided by an understanding of the original construction methodology, which the Fuse team gained from trawling through hundreds of the 1960’s detailed drawings! To add to our challenges, significant changes to the Building Regulations were brought in to play during the detailed design of this project, including changes to Part F (Ventilation), changes to Part L (Conservation of Fuel and Power) and the introduction of the new Part O (Overheating) regulation.

It quickly came apparent that we would need to fully refurbish the external wall build up from the inside, leaving the external concrete panels in place, being integral to the overall structural stability of the building. Fuse had to work with specialist manufacturers to ensure the right products were selected for this unusual building typology. Full fill Knauf RockSilk was proposed as the primary insulation product, which had to be secured to the rear face of existing concrete panels with aluminium self-adhesive stick pins – ideal for this project type.

Tackling the existing floors to upgrade their fire and acoustic properties resulted in us fully under-drawing the entire floor with Fireboard and encasing the steel floor joists as part of the fire protection strategy. The timber flooring on top acted as a secondary cross bracing between the joists and where the timber flooring met the external wall, as you would imagine, it did not form a perfect seal to the rear of the concrete external wall panels! Additional support angles were introduced to pick up the new internal wall studs, along with the introduction of fire stops at every floor level.

There were of course still various challenges along the way but one of the more notable ones was the presence of bats during the Construction Phase. Following a delicate but intrusive survey, bats were found hidden deep within the building fabric, which meant sufficient time was needed to plan, design and build the scheme, ensuring the welfare of the bats was not compromised. Temporary re-homing of the bats was undertaken by specialists, while care was taken to ensure the existing areas of habitation were not damaged or disturbed in any way, so the bats had their homes to return to – being creatures of habit!

Following the extensive strip-back to the building shell, works to clean, repair, and make good the listed concrete panels was completed, along with the installation of new triple-glazed windows throughout, replacing the original single glazed windows. The external windows replicate the original design intent of the ‘Off-White’ enamel panels used in the oriel windows and adjacent Derwent College, which compliments the colours of the interior and the original design intent.

The sustainable energy proposals for Derwent P focused on the construction of an energy efficient building, with a focus on substantially increasing the existing building’s thermal mass, and a passive approach to the fabric improvements. This included detailing the external walls to greatly improve the air leakage rates. The completed refurbished building benefits from a reduced energy output and improved internal environment for the building’s occupants. The mechanical services have been designed with automation in mind, to reduce energy wastage, whilst utilising high efficiency low energy motors, and sub-metering throughout.

The new interior design concept took inspiration from the original 1960’s interior, to create a simple/ stripped back interior using a neutral colour palette and natural materials influenced by its surroundings. The communal areas within the building have a muted palette of contemporary colours to define the private and public spaces. Natural light was maximised internally through widening the corridors and glazing the central staircase.

A technically challenging project created a very rewarding final scheme. It was a pleasure working with our client, the University of York, main contractor, Lindum Construction and the rest of the design team. The Project Team included:

Structure & Civils: BWB Consulting Ltd / Mechanical & Electrical: CPW / Quantity Surveyor & Project Management: AtkinsRéalis / Landscape Architects: Smeeden Foreman / Heritage Consultant: Lanpro Services / Planning Consultant: O’Neill Associates

Fuse Studios Limited, info@fuse-studios.com